Performative Biopolymer Design: Working Digitally with Plant-based Biogels

Instructors: Garrett Sutherlin Santo / Paul Sutherlin Santo / Andrew DePew

Dates: July 22, July 23, July 26, July 29 (10:00 – 13:00 PST)

Themes: Bio Design / Fabrication / Material Studies

Software: Rhino / Grasshopper

Number of Students: 60

Workshop is full please refer to live stream during and after the workshops

Description:

The integration of biological processes in design, both as natural and synthetic technologies, are rapidly dissolving long-held distinctions between the sciences, arts, and engineering while facilitating the evolution of more complex relationships between our built and natural worlds. As more bio-based methods of make filter into the digital workflows that support creative industry, designers are afforded incredible opportunity to explore the complex performance and versatility bio-materials offer. In this workshop, participants will learn to design, make, and 3D print customized biogels into multi-material biopolymer samples. The experience aims to provide a foundational understanding of novel biomaterials and a brief survey of contemporary explorations in bio-digital design focusing on concepts around sustainability, multi-materiality, and aesthetics.

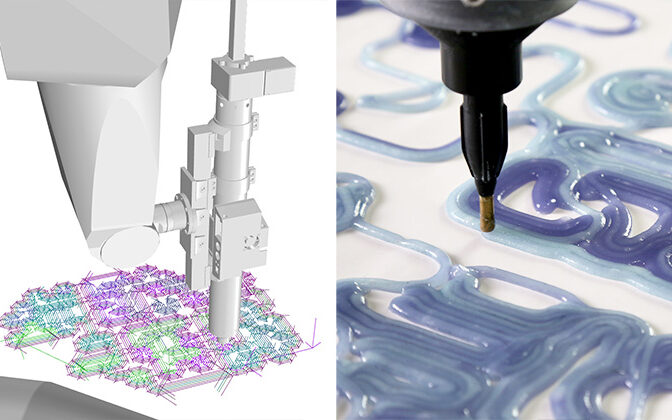

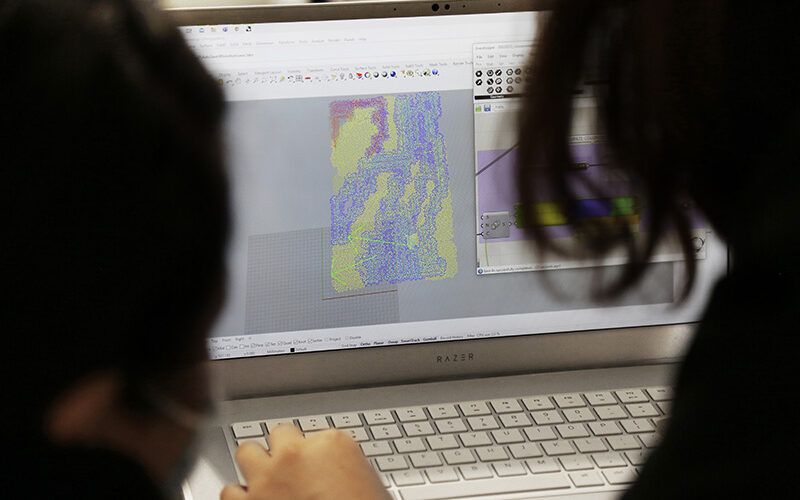

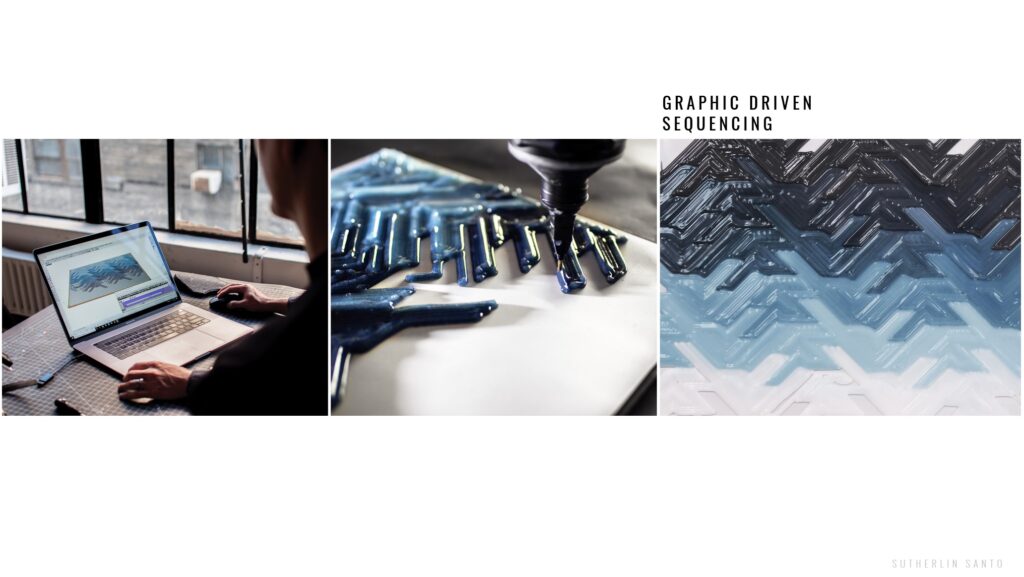

Included in the (4) sessions, participants will receive a tutorial demonstrating a simplified procedure for making biogel at home. This will be followed by an introduction to digital bio-printing design considerations, opportunities, and a technical walk-through of a Grasshopper to G-code workflow that will include methods for creating custom bio-gel 3D printing toolpaths from 2D images. The goal is to design material samples that utilize toolpath centered procedures to 3D print gradated biopolymer composites with customized sets of plant-based gels varying in opacity, color, and texture.

While not required, we encourage every participant to experiment with biogels at home during our workshop; the materials and supplies needed for the biogel recipe tutorial are listed in ‘Prerequisites’. To conclude the workshop, a selection of workshop bio-gel toolpaths will be printed in a live demo from our studio.

LEARNING OBJECTIVES:

Introduction to biomaterials in contemporary digital workflows

Methods of making extruder-ready biogel at home

Methods of 3D printing multi-material biopolymer designs

Methods to create planar and non-planar toolpaths from 2D images using Rhino/Grasshopper

Methods to export toolpaths as G-code for use with 3D printers and robots using Rhino/Grasshopper

WORKSHOP OUTCOMES:

Material samples (for those who make biogel at home)

Foundational knowledge and workflow for future independent bio-design research

Selected biopolymer material toolpath designs (~20x20cm) will be printed on livestream

Detailed workshop structure for each day :

Total Workshop Hours: 10.5

Time Zone: Pacific Daylight Time (PDT/PST/US West Coast) GMT -07:00

SAT, JULY 22, 2023 (10:00 – 12:30 PST): Intro Lecture & Bio-gel ‘cooking’ Tutorial

Note: this session includes a tutorial demonstrating a simplified process for making extrudable bio-gel at home; although not required, please see ‘Biogel Prerequisites’ for a materials and supplies list needed to participate in this tutorial.

SUN, JULY 23, 2023 (10:00 – 13:00 PST): Introduction to digital bio-printing design considerations, opportunities, and technical walk-through of grasshopper toolpath creation for bio-gels.

WED, JULY 26, 2023 (10:00 – 12:00 PST): Support Session

SAT, JULY 29, 2023 (10:00 – 13:00 PST): Live print demo of selected workshop bio-gel toolpaths and presentation of research findings; closing remarks.

Prerequisites (prior knowledge of topics, software), if any*

SKILLS:

Beginner to intermediate working knowledge of Rhino 7 and Grasshopper (required).

Basic operational understanding of 3D printers/robotics (preferred but not required).

SOFTWARE:

Rhino 7 / Grasshopper (required)

Photoshop / Any image editing software (preferred but not required)

HARDWARE:

Robot/3D printer with paste extruder (optional)

BIOGEL PREREQUISITES: (Optional)

This is a list of materials and supplies needed to make biogel at home, however, this is not a required component of the workshop.

½ lb Arrowroot starch / flour

½ lb Potato starch

16oz Vegetable glycerin

16oz White vinegar

Natural dyes / concentrated food coloring (optional)

Basic kitchen tools including:

Stove Top

Kitchen gram scale

Pot

Large spoon

Large plastic syringe / piping bag (optional, to manually test extrusion)

Thermometer (optional)

Blender (optional)

Baking sheet / silicone mat / flat non-stick surface (optional)

Instructors:

Garrett Sutherlin Santo:

Garrett works and teaches in art, architecture, and design with an emphasis on applied material research and emerging technology. He received undergraduate degrees in art and biogeography from UCLA and his Master of Architecture from SCI-Arc, where he continued design-research and taught advanced robotic fabrication. Currently, Garrett co-owns and operates Sutherlin Santo, a studio which centers on the use of advanced techniques that explore methods of fabrication which anticipate a future where design’s connection to nature and technology are symmetrical. Sutherlin Santo has been recognized internationally for work exploring the relationship of emerging digital processes, ecology, and traditional craft..

Paul Sutherlin Santo:

Paul co-owns and operates the research-driven design workshop, Sutherlin Santo, where he leads material exploration and project concept development. Having studied filmmaking and production design at Chapman University, Paul drives narrative development for the studio’s speculative design, orienting work toward a future where our technological and natural worlds are more closely aligned. Recently, Paul has lectured on design and sustainable materials at the International Design Culture Conference (IDCC) for Seoul University and previously conducted workshops on the robotic deployment of biomaterials for the SCI-Arc MS Architectural Technologies Design Lab.

Andrew DePew:

Andrew DePew is an architecture graduate and computational designer. He pursued and received an MS in Architectural Technologies at SCI-Arc. He stayed on at the school to help teach a seminar on robotically printing bio-gels, as well as assist in other robotic fabrication research projects. Andrew’s own work explores digital tools and fabrication as a way to develop integrated, sustainably-focused architectural systems.